Best VFD Repair in India, Master it:

10 Pro Tips for Reliable Restoration and Fixes!

Trusted VFD Repair Services Across India – Powered by Usha Automation and Services

At Usha Automation and Services, we understand that when Variable Frequency Drives (VFDs) stop working properly, your entire operation can come to a standstill. That’s why we offer fast, professional, and affordable VFD repair services across India—helping industries stay productive without delay.

Why VFD Repair Matters

VFDs play a vital role in controlling motor speed and energy consumption. Over time, they may face issues like overheating, software faults, or circuit failures. Without timely repair, this could mean prolonged downtime and rising costs. That’s where our expert team steps in—to get your systems back on track efficiently and reliably.

Our technicians are trained to handle all leading brands including Yaskawa, Danfoss, Delta, Siemens, Mitsubishi and more. Whether it's a minor glitch or a critical breakdown, we use advanced diagnostics and best-in-class tools to ensure your drive systems are repaired to factory standards.

What Sets Us Apart

1. Expert Technicians: Our team brings years of hands-on experience in diagnosing and repairing a wide range of VFD models.

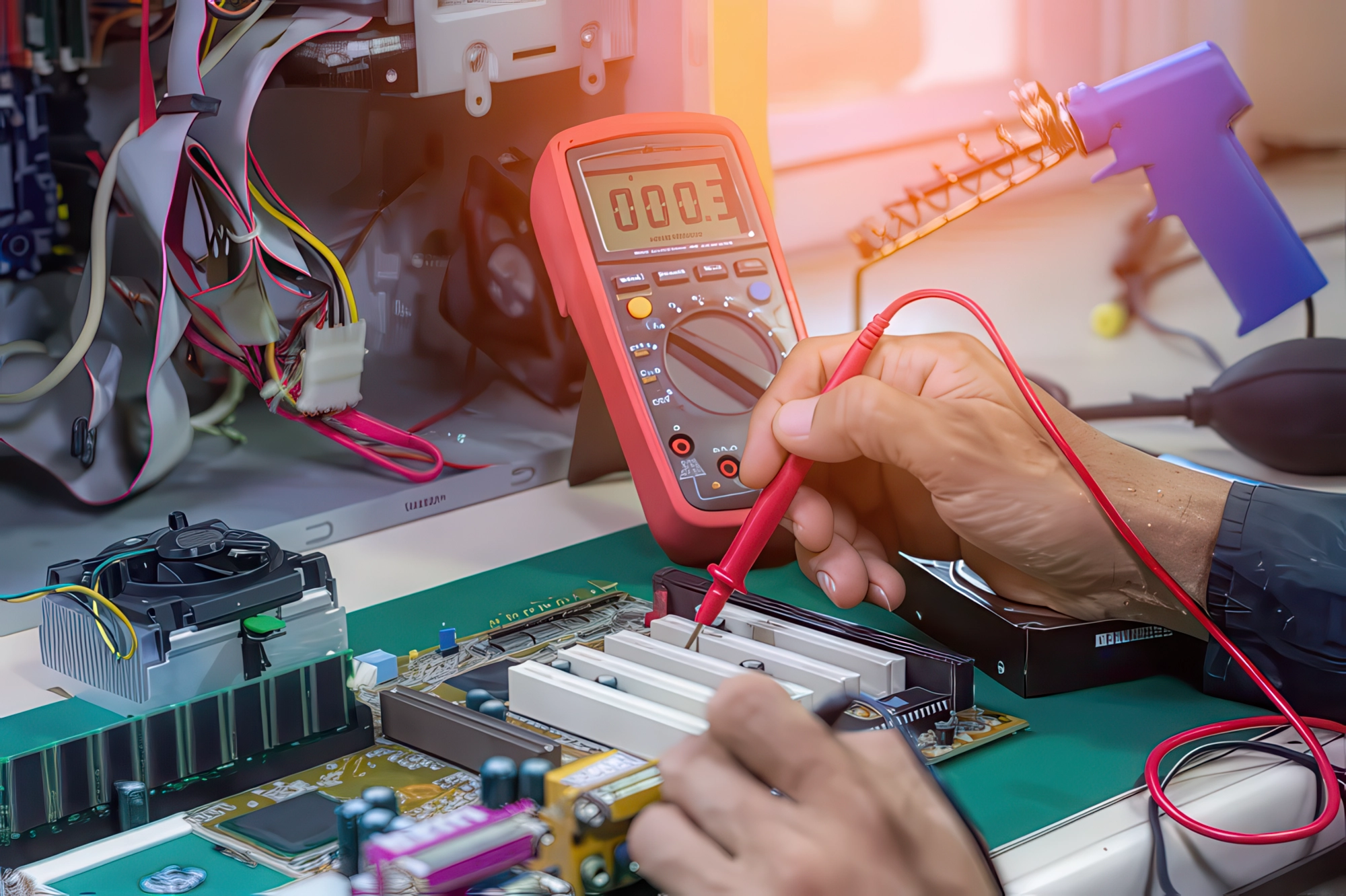

2. Cutting-Edge Equipment: We use state-of-the-art testing and repair tools to get to the root of the problem quickly.

3. Fast Turnaround: Our streamlined process ensures minimal disruption and speedy delivery.

4. Thorough Post-Repair Testing: Every VFD we service is tested under real working conditions to guarantee reliability.

5. Cost-Effective Service: We deliver quality results without the premium price tag, making us the go-to repair partner for industries nationwide.

Common VFD Problems We Solve

Our repair services cover a wide spectrum of VFD issues, including:

- 🔥 Overheating due to poor ventilation or overloaded components

- 🔌 Power Supply Failures affecting input/output connections

- 🔧 Faulty Control Boards and logic errors

- 💾 Software Bugs and firmware mismatches

- 🔊 Noise & Vibrations indicating mechanical/electrical faults

Extend the Life of Your VFDs

Our maintenance packages are designed to prevent failures before they happen. We offer:

- ✔️ Routine cleaning and component checks

- ✔️ Firmware verification and updates

- ✔️ Tightening of electrical terminals

- ✔️ Monitoring key performance metrics

Ready When You Need Us

No matter the size of your operation, Usha Automation and Services is here to deliver expert support and dependable repair solutions. We’re proud to be a trusted name in the automation industry—always just one call away.

Reach out to us today or visit ushaautomation.in to discover how we can help maximize the performance of your automation systems.

10 Pro Tips for Reliable VFD Repairs in India – Backed by Usha Automation & Services

Variable Frequency Drives (VFDs) are the unsung heroes behind modern-day industrial operations. They keep motors humming efficiently, reduce energy consumption, and fine-tune production processes to perfection. But like all technology, they’re not immune to wear, overheating, or signal faults. When that happens, Usha Automation & Services steps in with precision, expertise, and rapid turnaround VFD repairs across India.

Expert VFD Repair Services – Engineered for Reliability

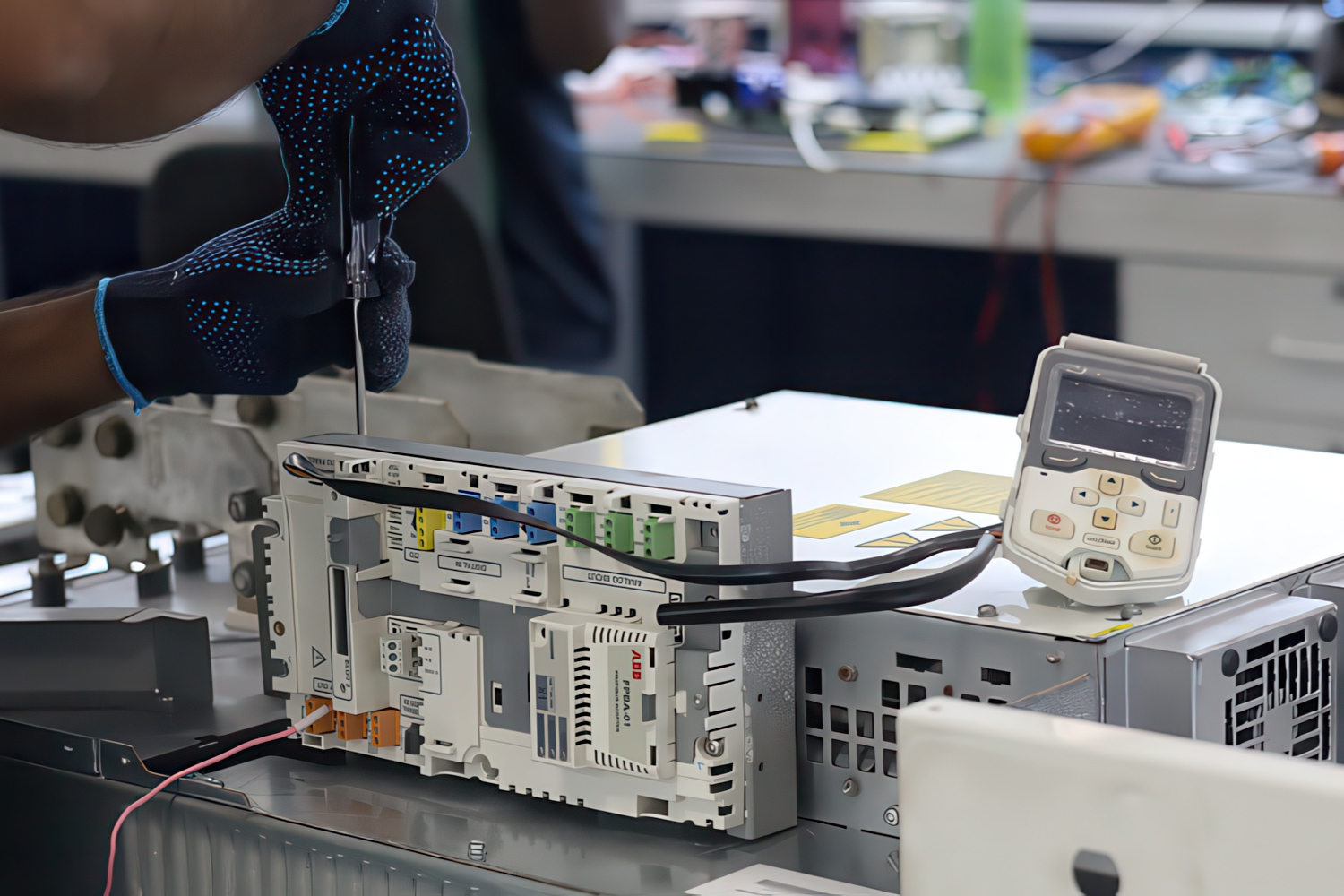

Our in-house team of drive specialists work with leading VFD brands like Yaskawa, Danfoss, Delta, and Siemens, restoring units suffering from performance loss, error codes, or hardware damage. With industry-certified diagnostics tools and years of practical experience, we repair VFDs across industries—from textile and food processing to heavy manufacturing and robotics.

Here are our top 10 professional tips and techniques to ensure your VFDs stay reliable, responsive, and ready for action:

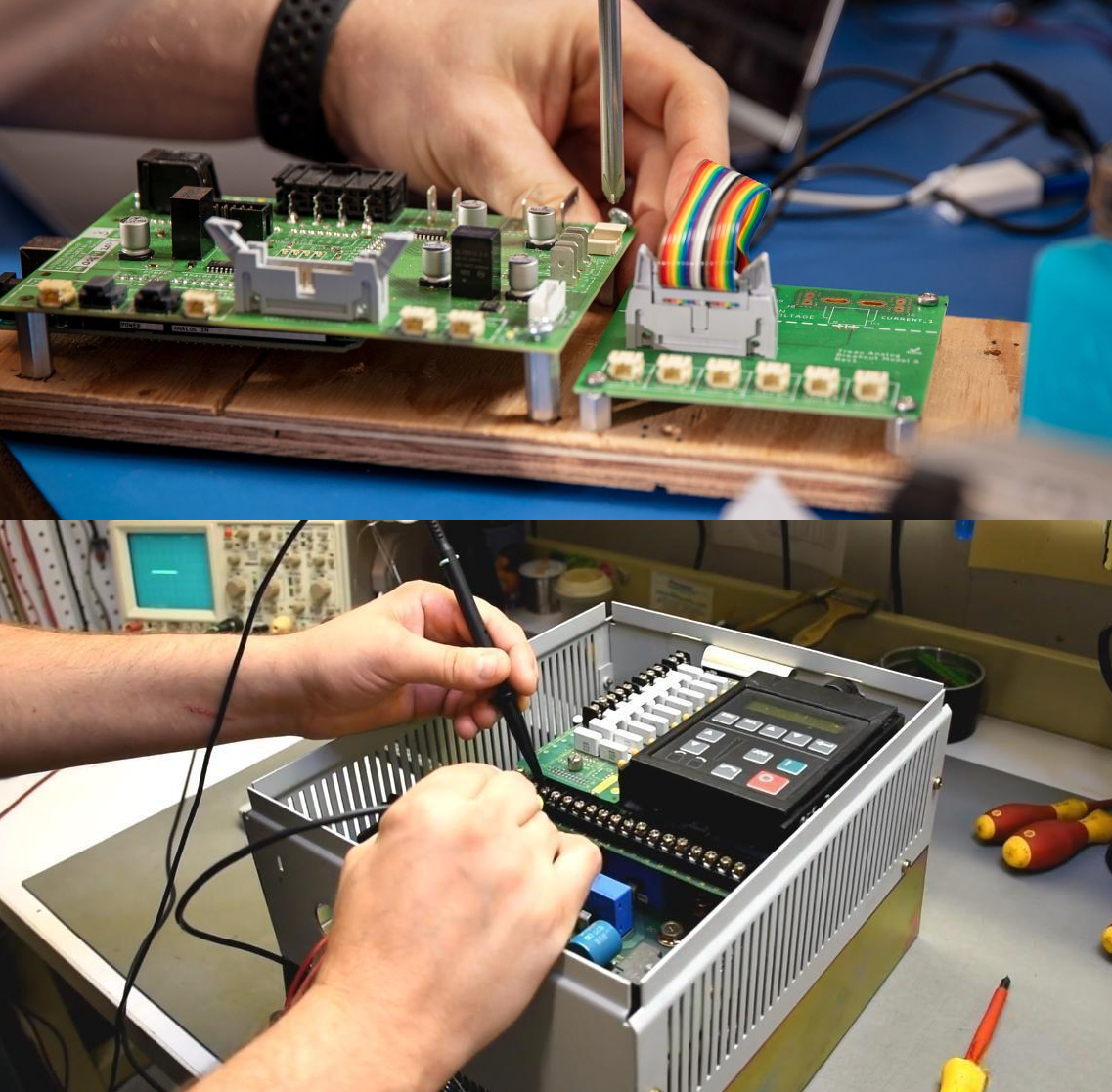

- Perform a Thorough Visual Inspection: Check for burnt components, swollen capacitors, loose connections, dust buildup, or discolored PCBs. Many faults (like blown fuses or charred resistors) are visible before deeper diagnostics.

- Test Input & Output Voltage with Precision Tools: Use a multimeter or oscilloscope to verify correct input voltage (3-phase balance) and output signals. Faulty IGBTs, diodes, or SCRs often cause irregular motor behavior.

- Inspect DC Bus Capacitors & Bus Voltage: Weak or bulging capacitors lead to unstable DC bus voltage. Measure capacitance and ESR (Equivalent Series Resistance) to detect failing capacitors before they cause shutdowns.

- Check & Repair PCB Traces: High current or heat can damage traces. Use a continuity tester to find broken paths, then re-solder or bridge them with precision tools.

- Update Firmware & Reset Parameters: Corrupted firmware or incorrect settings (e.g., motor Hz, acceleration time) cause erratic operation. Reload the latest firmware and reconfigure parameters per motor specs.

- Test & Maintain Cooling Systems: Overheating kills VFDs. Inspect fans, clean heatsinks, replace worn bearings, and reapply thermal paste on power modules to prevent thermal shutdowns.

- Diagnose Control Board Failures: Use logic analyzers or signal testers to check microprocessors, EEPROMs, and gate drivers. Faulty optocouplers or relays often mimic power stage issues.

- Analyze Error Codes & Historical Fault Logs: Modern VFDs store error histories (e.g., overcurrent, overvoltage). Decode these logs to pinpoint recurring issues before repairs.

- Inspect Motor & Cable Integrity: Ground faults, shorted windings, or damaged cables can trip VFDs. Perform insulation resistance tests (megger) and check for phase imbalances.

- Simulate Real Load Conditions Post-Repair: Test the VFD under variable loads (using a dummy load if needed) to ensure stable operation before reinstalling it in the system.

Advanced VFD Techniques Exclusive to Usha

Our repair engineers use signal tracing and component-level diagnostics to identify intermittent issues that standard testing can miss. We also employ high-frequency ultrasonic cleaning to remove carbon and oxidation from critical boards—reviving older drives others might scrap.

We handle everything from blown input fuses and IGBT bridge failures to control card reprogramming and dynamic brake circuit issues. Combined with our preventative maintenance tips, clients often save on costly replacements and avoid prolonged downtime.

Why Trust Usha Automation for VFD Repairs?

- Pan-India Service Reach: We serve businesses across India with door-step pickup and delivery for VFD units.

- Fast Turnaround: Our optimized workflow ensures most VFDs are repaired and returned within 2–5 working days.

- Brand-Agnostic Repairs: We support Delta, Yaskawa, Danfoss, Siemens, ABB, and many more—no bias, just results.

- Warranty-Backed Repairs: Every VFD is delivered with a performance warranty and detailed service report.

From single-unit repairs to bulk servicing contracts, Usha Automation and Services is trusted by industries of all sizes for fast, reliable, and professional VFD repair in India.

Ready to bring your drives back to life? Contact our expert team today! for consultation, diagnostics, and affordable repairs that work the first time—and last a long time.

Make a Business Enquiry!

――― Brands ―――

Our Trusted Brands

Explore our range of trusted brands and discover high-quality solutions for your automation needs.